"The challenge was complex and uncertain, but the methodology, proximity, and high technical and communication quality of the Dribia team have been key to making the project a complete success".

FEATURES

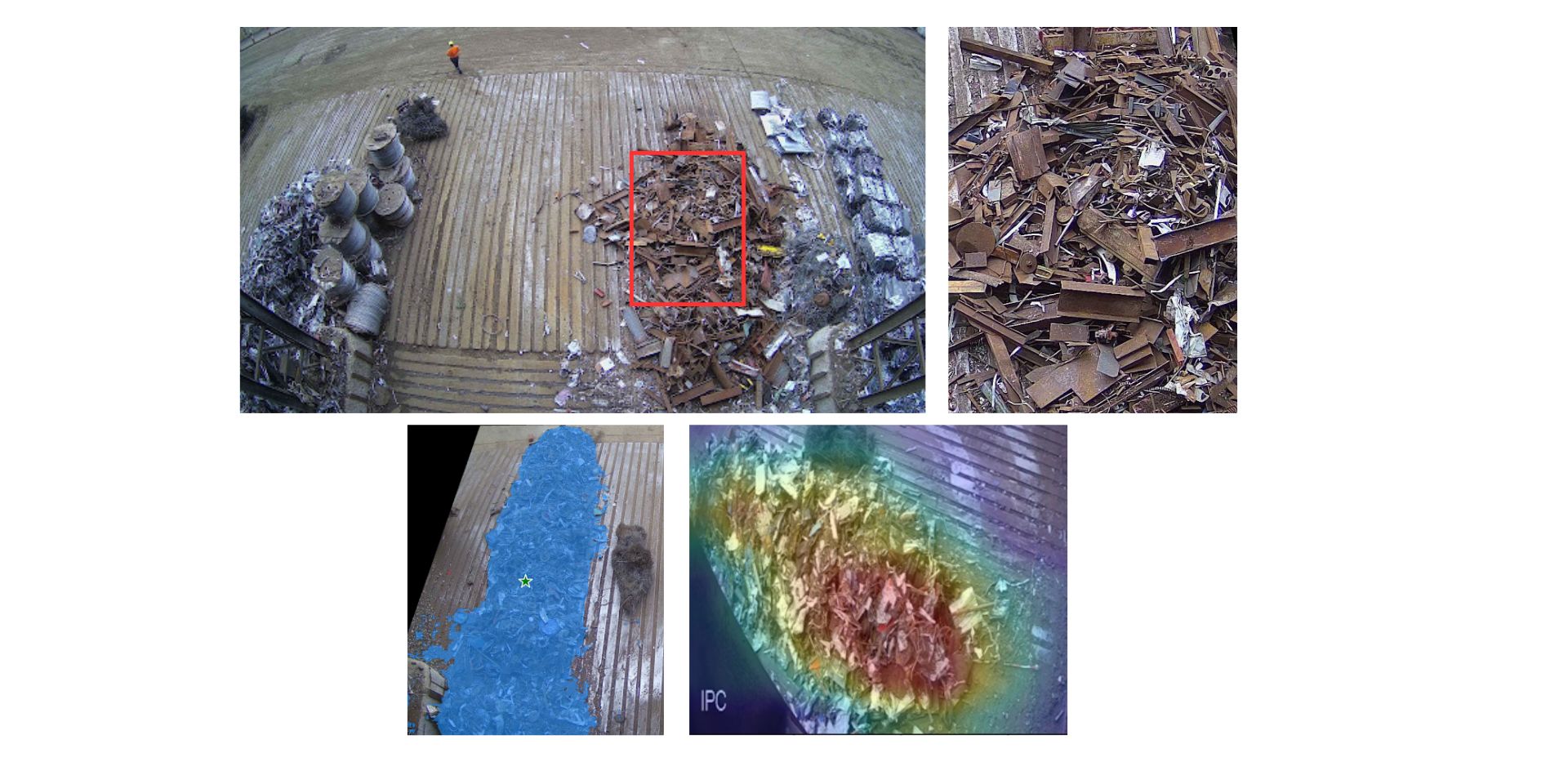

Image recognition based on deep neural networks for scrap metal classification based on its quality.

IMPACT

Automation of 70% of classifications that involved human presence and risk of occupational accidents.

ACHIEVEMENTS

98% accuracy in pre-classification and 84% in purchase quality.

BUSINESS PROBLEM

Identifying precisely and objectively the percentage of quality of each material in scrap unloadings from suppliers is key to a better assessment in the purchase by Celsa. The current method is slow, requires the physical presence of the sorters near the scrap, with a high cost in transport time and with the possibility of a work accident. An assessment of scrap without bias can allow for better negotiation and management of incidents in the assessment with suppliers.

DRIBIA’S SOLUTION

An algorithmic solution has been built and integrated capable of capturing images from specially placed static cameras and identifying their different qualities through static camera images. Specifically, a machine learning model based on deep convolutional neural networks has been trained, with which the images obtained from the fixed cameras are processed. The detection of qualities is generated in real time when the operators make the request to the system, and the prediction can be assessed at the time. In addition, the possibility of visually analyzing the prediction of the neural network has been developed in parallel using explainability techniques, which mark the areas in each image that the network has considered relevant during the prediction process. This solution allows classification to be carried out without human interaction on site, eliminating security problems. In addition, it allows increasing the objectivity of the assessment and streamlining the process.